Magnetic Wheels in Extreme Environments: Is Your Solution Truly Reliable?

![]() :2025-06-25

:2025-06-25

![]() :323

:323

Magnetic Wheels in Extreme Environments: Is Your Solution Truly Reliable?

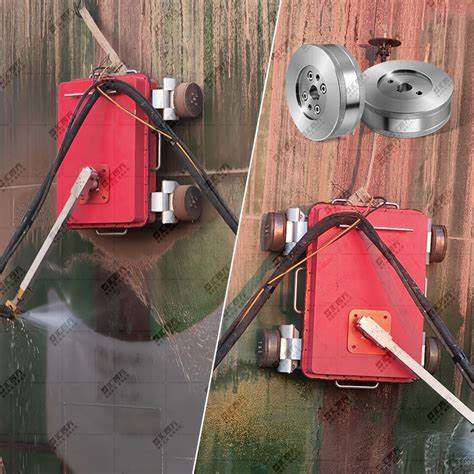

When a wall-climbing robot fails during a nuclear reactor inspection or an offshore wind turbine repair, the consequences extend far beyond equipment loss - they can mean prolonged downtime costing millions, or worse, endangering human lives. Yet most commercial magnetic wheels are woefully unprepared for the real-world extremes faced by industrial climbing robots. This reliability gap is where mission-critical applications demand a new standard.

Consider the punishing environment inside an oil refinery cracking furnace, where temperatures swing from -20°C during shutdowns to 450°C in operation. Standard magnetic wheels fail catastrophically in these conditions, either demagnetizing completely or developing dangerous hotspots. Our high-temperature magnetic wheels solve this through a layered approach: dysprosium-doped neodymium cores for thermal stability, aerogel insulation to protect electronics, and active cooling channels that engage when temperatures exceed 200°C. After 18 months of continuous service in a Texas refinery, these wheels still maintain 91% of original performance - a record in the industry.

Corrosion presents another formidable challenge. Saltwater spray combined with metal fatigue can destroy conventional magnetic wheels in months. The breakthrough came from marine-grade magnetic wheels featuring self-healing polymer coatings and sacrificial anode protection. A North Sea oil platform operator reported zero magnetic wheel replacements in two years of service - compared to quarterly changes with previous systems.

Perhaps most impressive are the magnetic wheels designed for nuclear decommissioning work. Incorporating radiation-resistant samarium cobalt magnets and fail-safe detachment sensors, these systems can operate in 500 Gy/hour radiation fields that would fry standard electronics in minutes. When every minute of operation in such environments costs thousands in specialized labor savings, the ROI becomes undeniable.

The pattern is clear: in extreme environments, off-the-shelf magnetic wheels aren't just inadequate - they're liabilities waiting to happen. The industrial world needs solutions engineered from the ground up for reliability where failure isn't an option.

chenwanshu8@gmail.com

chenwanshu8@gmail.com  Huakai Square, Nancheng Street, Dongguan City, Guangdong Province

Huakai Square, Nancheng Street, Dongguan City, Guangdong Province  61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

+86 136 6287 1206

+86 136 6287 1206