How Smart Algorithms Enable Self-Learning Magnetic Wheel Adhesion?

![]() :2025-07-25

:2025-07-25

![]() :461

:461

How Smart Algorithms Enable Self-Learning Magnetic Wheel Adhesion?

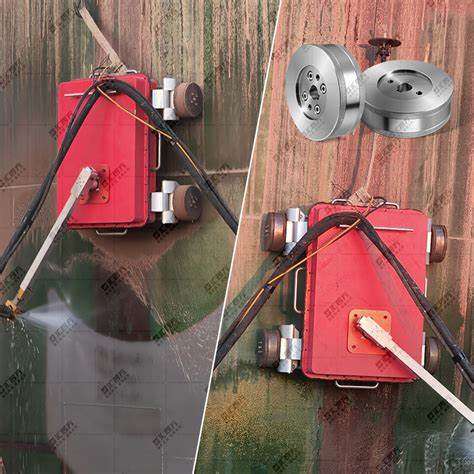

The next evolution in magnetic wheel technology isn't about stronger magnets - it's about smarter ones. Traditional wheels apply the same brute-force approach whether climbing a pristine steel plate or a corroded, pitted surface. Our self-learning magnetic wheels change this paradigm by continuously adapting to surface conditions using onboard AI processors.

The system works through three-phase learning:

1. Initial surface mapping using ultrasonic and eddy current sensors

2. Real-time adjustment of magnetic force distribution

3. Long-term pattern recognition that predicts optimal settings

At a Chinese nuclear facility, these wheels achieved 99.2% adhesion reliability across 47 different surface conditions - from polished stainless steel to heavily rusted carbon steel. The wheels actually improve with use, building a library of optimal settings that transfer between similar surfaces.

For operators, the benefits are transformative. Instead of manually programming wheel parameters for each new environment, the robots now adapt autonomously - cutting setup time by 80% while improving safety margins. In hazardous environments where every second counts, this self-learning capability isn't just convenient - it's revolutionary.

chenwanshu8@gmail.com

chenwanshu8@gmail.com  Huakai Square, Nancheng Street, Dongguan City, Guangdong Province

Huakai Square, Nancheng Street, Dongguan City, Guangdong Province  61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

+86 136 6287 1206

+86 136 6287 1206