Magnet Climbing Robot Revolutionizes High-Risk Industrial Maintenance, Boosting Efficiency by 3-5 Times

![]() :2025-09-16

:2025-09-16

![]() :379

:379

Magnet Climbing Robot Revolutionizes High-Risk Industrial Maintenance, Boosting Efficiency by 3-5 Times

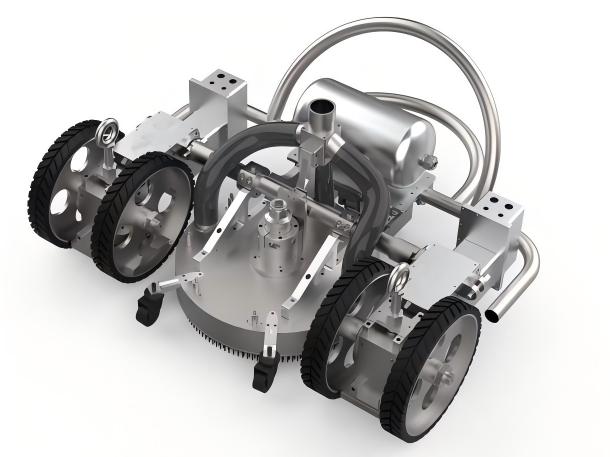

In recent years, an advanced device known as the Magnet Climbing Robot is fundamentally transforming traditional maintenance methods in industries such as storage tanks, ships, and wind power. It successfully replaces manual labor, efficiently performing a series of complex tasks including abrasive blasting, painting, welding, inspection, and cleaning. Practice has shown that this technology can increase work efficiency by 3 to 5 times, completely avoiding the significant safety risks associated with manual high-altitude operations and significantly saving labor costs for enterprises.

The core advantage of the Magnet Climbing Robot lies in its unparalleled adaptability and stability. Through a powerful magnetic adhesion system, it can firmly attach to vertical, curved, or even inverted metal surfaces, moving and operating steadily in complex and harsh working conditions. Furthermore, the robot integrates high-definition cameras, various sensors, and an intelligent control system, enabling real-time data collection and transmission to the ground control station for remote precision operation and high-quality task execution.

For enterprises, deploying the Magnet Climbing Robot signifies a dual enhancement in operational safety and economic benefits. Traditional high-altitude operations not only place extremely high demands on workers' skills and psychological resilience but also carry high accident risks and insurance costs. The application of the robot entirely eliminates safety hazards such as falls and health damage for personnel. It also reduces reliance on specialized workers, cutting training expenses and losses from work stoppages due to safety incidents.

Looking ahead, with the deep integration of Artificial Intelligence (AI) and the Internet of Things (IoT), the Magnet Climbing Robot will evolve towards greater intelligence and autonomy. It is set to become an indispensable part of industrial operation and maintenance automation, poised to play a key role in more high-risk and challenging scenarios, continuously contributing value to safe production, cost reduction, and efficiency improvement across the industrial sector.

chenwanshu8@gmail.com

chenwanshu8@gmail.com  Huakai Square, Nancheng Street, Dongguan City, Guangdong Province

Huakai Square, Nancheng Street, Dongguan City, Guangdong Province  61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

+86 136 6287 1206

+86 136 6287 1206