In the magnet world, in addition to our common bar, hoof, ring and other standardized magnets, there is also a kind of different shapes, unique function of the magnet - special-shaped magnet. With their non-standardized shape and customized design, these magnets play an irreplaceable role in many fields. This paper will deeply discuss the definition, characteristics, manufacturing process and its application in various fields of shaped magnet.

Parameter:(please contact customer service for more parameters)

| Shape | Dimension | Material quality | Coating | Magnetic property | Temperature resistance | Sample | Sample time |

| customizable | customizable | NdFeB | Zinc/Nickel/Epoxy/Phosphating | N35-N54 | 80-150℃ | Yes | 5~7 Day |

Features of shaped magnets:

● A variety of shapes: The shape of the special-shaped magnet can be any imaginable shape, from simple geometric figures to complex three-dimensional structures, and can even mimic the shape of natural or man-made objects.

● Function customization: In addition to the customization of the shape, the magnetic properties of the shaped magnet can also be adjusted according to needs, such as the strength of the magnetic force, the distribution of the magnetic poles, etc.

● High-precision manufacturing: The manufacturing process of special-shaped magnets usually requires high-precision processing technology and equipment to ensure that the shape and performance of the magnet meet the design requirements.

● Wide range of applications: Due to its unique shape and performance, shaped magnets are widely used in many fields such as scientific research, industrial production, and daily life.

Manufacturing process of shaped magnet:

● Raw material selection: According to the application needs to choose the appropriate magnet material, such as Ndfeb, ferrite and so on.

● Shape design: Shape design according to application requirements and draw detailed drawings.

● Mold making: According to the design drawings, mold is made for forming magnets.

● Molding and curing: The magnet material is placed in the mold for molding, and then cured by heating or pressurizing.

● Magnetization: magnetizing the molded magnet to make it have the required magnetic properties.

● Inspection and testing: inspection and testing of the manufactured special-shaped magnet to ensure that its shape, size and performance meet the design requirements.

Application field:

● Industrial production: In the field of automated production lines, sensors, motors, etc., shaped magnets are widely used because of their unique shape and performance.

● Daily life: Shaped magnets are also often used in toys, artworks and other daily items to increase the interest and uniqueness of the product.

● Medical health: In the medical field, shaped magnets are also used to make magnetic therapy products, such as magnetic therapy patches, magnetic therapy pillows, etc., for relieving muscle pain and promoting blood circulation.

● Scientific research: In the research of physics, materials science and other fields, shaped magnets are often used to produce specific magnetic field distributions for the study of the magnetic, electrical and other properties of substances.

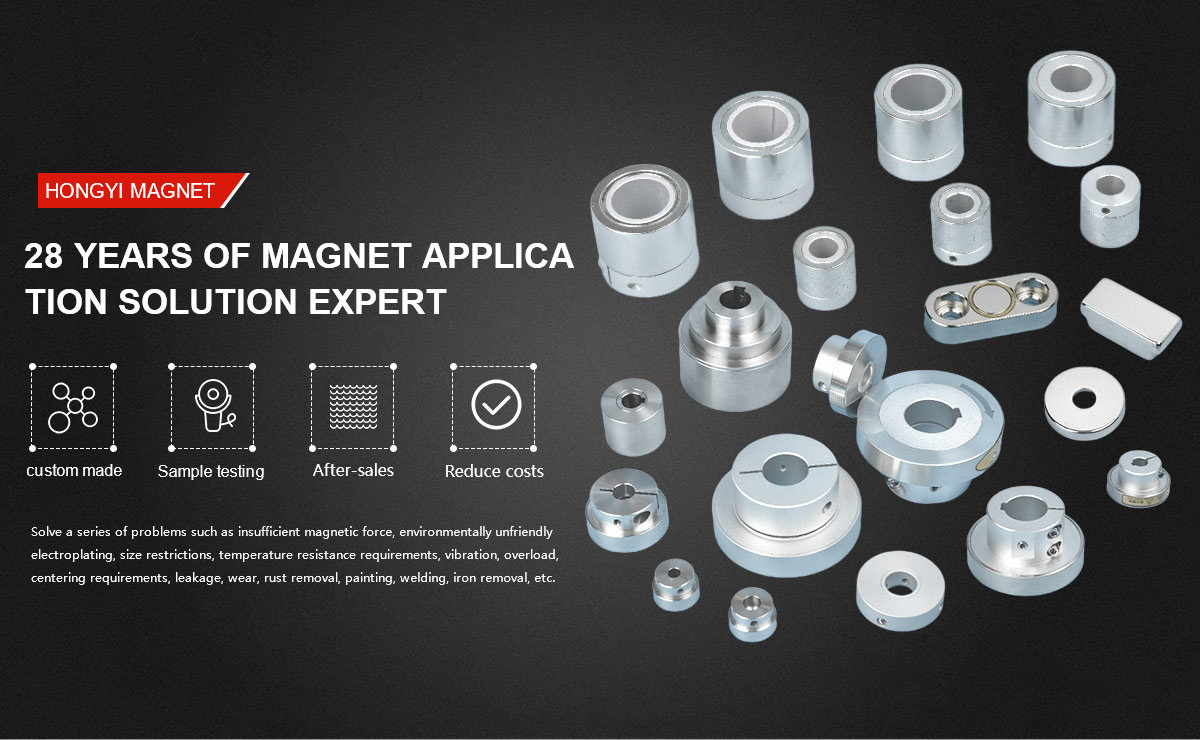

COMPANY ADVANTAGE

High-quality products and professional services

RICH EXPERIENCE

Rich experience in rare earth

magnet manufacturing

PROFESSIONAL

Strict control of details from

beginning to end

ABILITY

SALES OF MAGNETS EXCEEDED

50 MILLION YUAN

APPLICATION

High-quality products and professional services

Company Factory

High-quality products and professional services

chenwanshu8@gmail.com

chenwanshu8@gmail.com  Huakai Square, Nancheng Street, Dongguan City, Guangdong Province

Huakai Square, Nancheng Street, Dongguan City, Guangdong Province  61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

61 Wangsha Road, Hongmei Town, Dongguan City, Guangdong Province

+86 136 6287 1206

+86 136 6287 1206